DIY keyboard project - anyone up to collab?

Jan 25, 2019 22:33:07 GMT

admin, robertlanger, and 2 more like this

Post by ben on Jan 25, 2019 22:33:07 GMT

Does any of you have some knowledge in capacitive touch keyboards?

I'd love to do some etching to make a nice looking and functional keyboard. I'm totally open to collaborate with anyone who's up for it. But the problem is - how to actually make it? Any sort of schematics..?

A short story behind: I have an old Korg touch board, the chip wasn't working anymore, or with a lot of glitches, so I took it apart. Also there's X-Y touch sensitive pad, which I'm going to implement in my AE modular system for sure. Touch sensitive keys work quite well, but how to make them do two functions at the same time - to have pressure sensitivity (for instance for volume, filter, etc.) and the other thing to have them send a "gate" function (touch sensitivity/capacitive touch) - just a simple on/off signal which would further go to VCA etc.?

Was searching online, and found the only thing how capacitive touch keys work - it has to send/receive a pulse and when you're touching it - it makes it on or off. This can be achieved with 555 timer, Arduino and any other type of thing which can produce and receive PWM. But then the question is - if I run a PWM via those pressure sensitive keys - how to keep the second operation running - pressure sensitivity, if it's going to receive and send PWM, it's going to do one function and only, i.e. to send a square wave signal.. But it would be cool to feed 5V to it and then once you press it - depending of how hard you press it, it sends a different signal to filter or VCA for volume control.

There's two projects which I'd like to combine from Quincas "Synth DIY Guy" from YouTube:

1)

2)

Anyways, I guess if I would be able to figure this out, it would be possible to make my own keyboard with etched copper (and anyone who would be willing to collaborate). I work with metals, so to plate copper with silver or gold would not be a problem, because copper tends to oxidise quite fast.

The other technical abilities I could add to this project for manufacturing/making a few prototypes - etching, 3D printing, soldering, metal plating, casting (metal, rubber, resin).

Once I stepped into AE modular world it just came up as a natural thing for DIY and maybe even more advanced projects as a hobby.

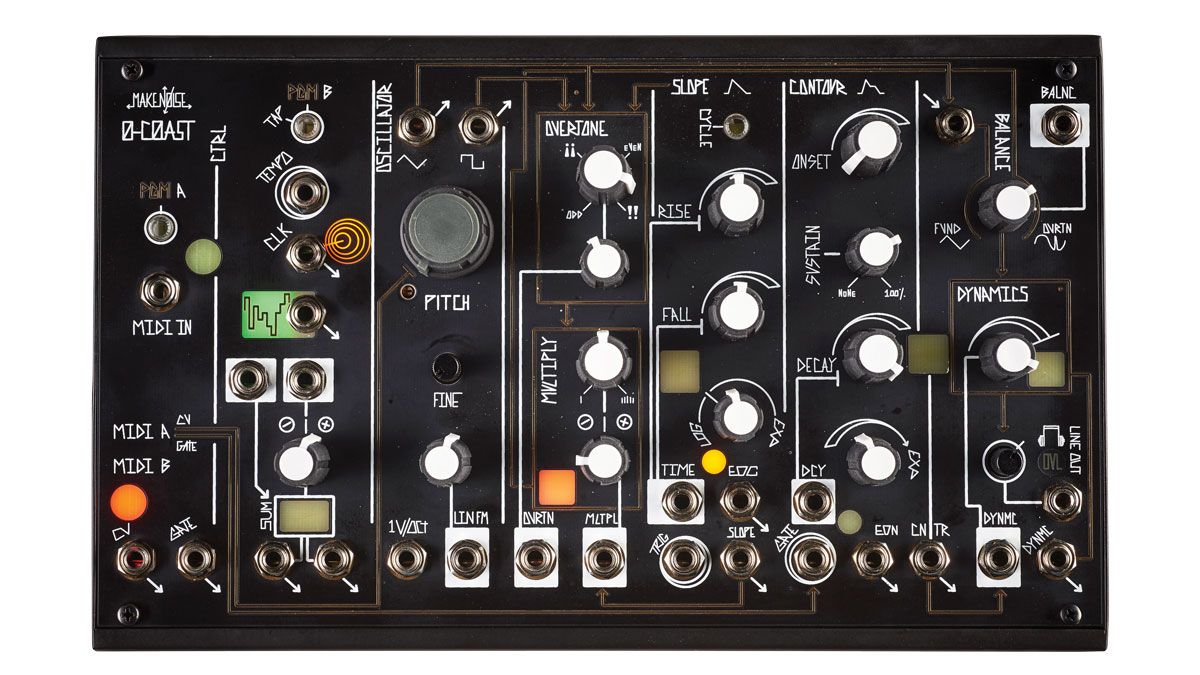

Below - Korg 12 key pressure sensitive keyboard I took apart.

I'd love to do some etching to make a nice looking and functional keyboard. I'm totally open to collaborate with anyone who's up for it. But the problem is - how to actually make it? Any sort of schematics..?

A short story behind: I have an old Korg touch board, the chip wasn't working anymore, or with a lot of glitches, so I took it apart. Also there's X-Y touch sensitive pad, which I'm going to implement in my AE modular system for sure. Touch sensitive keys work quite well, but how to make them do two functions at the same time - to have pressure sensitivity (for instance for volume, filter, etc.) and the other thing to have them send a "gate" function (touch sensitivity/capacitive touch) - just a simple on/off signal which would further go to VCA etc.?

Was searching online, and found the only thing how capacitive touch keys work - it has to send/receive a pulse and when you're touching it - it makes it on or off. This can be achieved with 555 timer, Arduino and any other type of thing which can produce and receive PWM. But then the question is - if I run a PWM via those pressure sensitive keys - how to keep the second operation running - pressure sensitivity, if it's going to receive and send PWM, it's going to do one function and only, i.e. to send a square wave signal.. But it would be cool to feed 5V to it and then once you press it - depending of how hard you press it, it sends a different signal to filter or VCA for volume control.

There's two projects which I'd like to combine from Quincas "Synth DIY Guy" from YouTube:

1)

2)

Anyways, I guess if I would be able to figure this out, it would be possible to make my own keyboard with etched copper (and anyone who would be willing to collaborate). I work with metals, so to plate copper with silver or gold would not be a problem, because copper tends to oxidise quite fast.

The other technical abilities I could add to this project for manufacturing/making a few prototypes - etching, 3D printing, soldering, metal plating, casting (metal, rubber, resin).

Once I stepped into AE modular world it just came up as a natural thing for DIY and maybe even more advanced projects as a hobby.

Below - Korg 12 key pressure sensitive keyboard I took apart.